1. What Are The Liquid Bags?

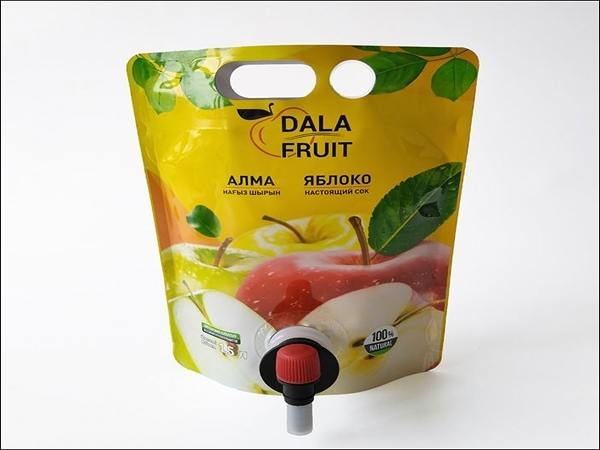

Liquid bags are a kind of liquid product packaging, you can use three-layer or four-layer laminate material. You can use liquid bags to pack different kinds of liquid products, such as juice, beverages, drinking water, etc.

If you have any needs for liquid pouches, plastic liquid bags, liquid mylar bags, clear liquid bags, please welcome to contact Sea Faith Plastics Packing.

2. What Are The Benefits Of Using Liquid Bags?

Keep Liquid Products Fresh

The most common contaminants to liquid products are moisture, oxygen, dust, and UV light; if the bag cannot resist these contaminants, it’s of no use.

It’s important to consider whether or not the bag can resist these factors. Liquid bags resist all these and ensure that the temperature is cool, suitable for liquid products. Furthermore, they are sealed well, making it hard for dust or germs to enter the pouch.

Flexibility and Convenience

Liquid bags are squeezable, making that they occupy the least space possible. The bags can be packed close enough that no space is wasted. For other packaging products, this is not possible.

If you try to squeeze, they either break or lose their form permanently. However, this is not the case with liquid bags, you can squeeze them, and they will still regain their shapes.

With these bags, you can put them in your pocket and take a walk or ride comfortably. If you carry a bottle on a walk, it feels uncomfortable as compared to liquid bags.

Refrigerator Criterion

In many cases, we store our consumable products in a refrigerator, and it becomes critical to check the compatibility of your storage method with the refrigerator.

Bottles can break inside the refrigerator and give you work of cleaning. On the other hand, in liquid bags, the content remains original with its taste, and your refrigerator lasts for a long. Bags are suitable for any atmospheric condition.

Easy Transportation

Products need to reach the intended consumer; therefore, factoring in how to transport the products to their destination is important. Liquid bags are lightweight and flexible, and they can be carried in large numbers. They save on transportation costs because fewer trucks will be required to transport them.

Cost-Effective

Money is limited, and if there is a way you can save it, grab the opportunity. Liquid bags offer you this opportunity to reduce the cost of production because they are cheaper than other packaging methods.

3. What Are The Productions Process Of Liquid Bags?

- Purchasing Raw Material

- Making Printing Copper Plate and Making Bottom Gusset Mould

- Printing As You Offered Printing Files

- Laminating Material

- Dividing The Laminated Material

- Maturing 24 Hours Or More Time To Keep The Laminated Material To Be Dry

- Bag-Making

- Inspection of Finished Bags

- Packing

- Arranging Shipment Out

4. What Are The Suitable Material For Liquid Bags?

The liquid bags mainly used materials are Aluminum foils, polypropylene, PET, NY, PE, VMPET, and Kraft paper.

Each material has its advantage over the other. However, the most important factor is the compatibility of the bag with the content.

In many cases, the material used is durable and resistant to external factors such as air, dust, moisture, and germs. More so, it’s lightweight making the bags flexible and consumer-friendly.

5. Which Factors Are Important To Consider Before Choosing Liquid Bags?

Cost

It’s critical to consider the cost of liquid bags; you don’t want to make orders of bags that will be way above your budget. It would help if you acquired liquid bags that are affordable.

The Importance Of The Material

The material used to make liquid bags must be compatible with the substance to be packed in it. There’re bags made for various purposes; there are those meant to carry consumable products, and others carry non-consumable products. Therefore, having the knowledge of which material is used to make the bags is important.

Supply Continuity

As a business person, you want to have the assurance that your products are always available in the market, and to do this, you must have a flow of bags in for you to pack your products and take them to the market.

However, if the supplier cannot continuously supply you with the liquid bags, you will have shortages that are not a good thing; somebody else takes advantage of that, and you end up losing your market share.

The Possibility Of Customization

Liquid bags that allow you to customize enable you to make your products unique and attractive in the market. You can distinguish your products from the competitors, and your products can be easily identifiable in the market.

Every business person wants to meet the desires of their customers, and this is possible with liquid bags because you can put logos, text, and graphics as you desire.

5. What Are The Standup Liquid Bags?

These are liquid bags that can remain standing on their own. The gussets are fit on different sides of the bag, making it appealing when displayed. Mainly, stand bags have gusseted bottoms that make them stable when standing.

These bags have impeccable overlaid materials making them the best choice for many consumers. This material deters interaction of the content with microorganisms, oxygen, and Uv light.

The materials are also suitable for customization, whereby you can brand your products in the best way possible. Additionally, the bags can have additional features to make them more convenient for consumers.

Sea Faith Plastics Packing can add these features to our customers because we want them to get the best from our products.

Stand bags look majestic on shelves because of their upright posture making them appear royal. Filling and dispensing content is smooth, whereby you can evacuate up to 99%. Its barrier proof is durable, and convenient for consumers: they can carry it around.

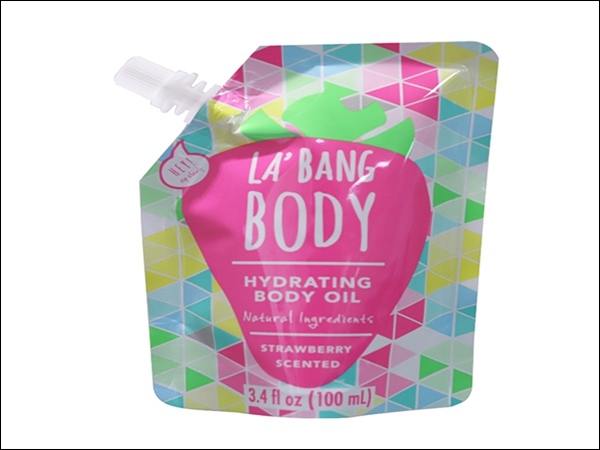

6. What Are Shaped Liquid Bags?

Shaped liquid bags are designed in different shapes that are unique and attractive to the customers. There are various types like round corner-shaped bags, squeezable shapes, hourglass shapes, and die-cut shapes. Each design is important because it makes the bag distinct from others.

Mainly, the material that is used to make bags is polyethylene. However, other materials may be used or be combined to produce a strong bag. These materials are durable and resistant.

These types of bags have several factors that make them appealing in the market. Its offers 100% protection against contaminants and preserves the taste, aroma, and nutrients of the content.

It’s also suitable for branding because it has a large surface area to print on. Its bottom enhances display, and its beauty is attractive to consumers.

7. What Are The Gusset Liquid Bags?

These are bags made with materials such as rubber, plastics, or metal and help them expand. The ability to expand makes these bags unique and carries more content because they can create more room.

The bag can be gusseted on the bottom or side, where they derive their name. These bags offer you packaging liquid products that have room for branding and preserving your nutrients.

These bags are durable and versatile, making them resistant to punctures. The material is also suitable for deterring external factors like moisture, UV light, dust, oxygen, and odor.

The bottom gusset bags stand on their own on the retail shelf giving clients visibility to logos, text, and graphics.

The bags have different colors making them attractive to the consumer and also suitable for product branding. With these types of bags filling and dispensing is smooth both for the manufacturer and consumer.

8. What Are The Fin Seal Liquid Pouches?

The fin seal liquid bags are well sealed in tamper-resistant material; they are plain, printed, transparent, or opaque. The bags are a good preservative method. Mainly, the materials used to make these bags are films, foils, and this has earned this type of bag many names, such as horizontal and vertical bags.

The outer layer of these bags is resistant to light, dust, moisture, and air. The seals are sealed well that there are no leakages. The material used in the manufacturing process allows the bags to be flexible, lightweight, and squeezable.

The display of these pouches is attractive because they can stand alone on the shelf. More so, filling and evacuation of liquid are smooth as its facilitated be a suitable closure method.

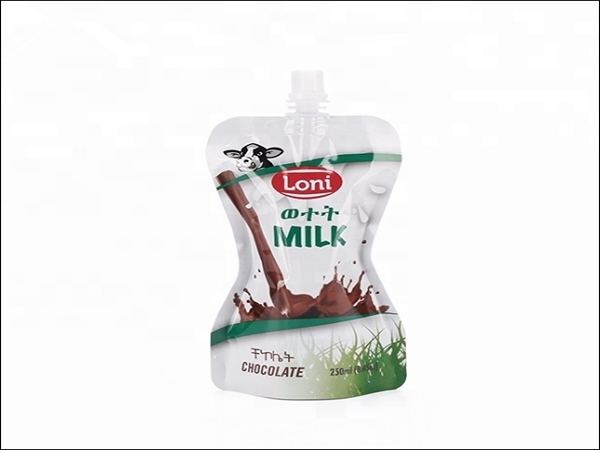

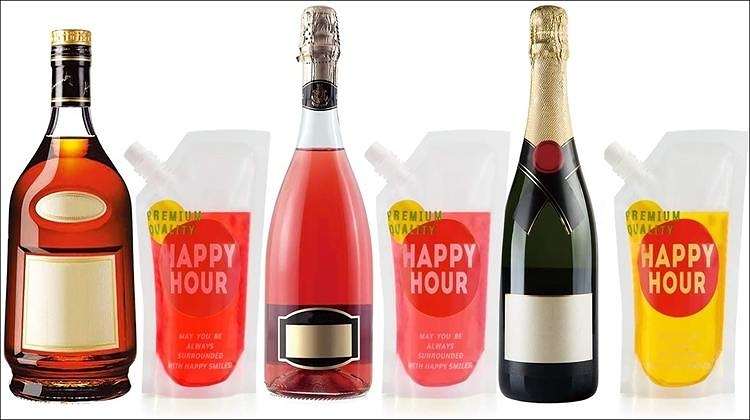

9. What Are Spout Liquid Bags?

Spout liquid bags are fitted with a perfect spout that facilitates a smooth evacuation and filling process. This closure method makes these bags unique and effective.

Additional features make these bags user-friendly, such as squeezable valves, push-pull, and screw closures.

These bags increase the longevity of the content because the closure methods prevent interferences from the outside. Additionally, the spout enhances the filling and dispensing of the liquid from the bags.

The cool aesthetic nature in color, design and shapes of these bags make them attractive to the consumers.

These bags are fit for refrigeration because their layers respond quickly to refrigeration. More so, it’s easy to handle and carry when hiking, walking, or riding because it’s lightweight and flexible.

10. What Are The Flat Liquid Bags?

The flat liquid bags are designed in the shape of a sack or a bag. Its produced by refined materials or drawstrings materials and polyethylene.

These bags expand when filled with substance creating more space; this is an advantage because they can carry more.

With this type of liquid bag, branding is easy because the outer allows for customization. The seals are fit tightly, making the bags accident-proof and resistant to contaminants like moisture, germs, and air.

The bags are suitable for sports activities because they are lightweight and flexible. It’s consumer-friendly because of its design and colors.

11. Why Do You Use Liquid Bags To Pack Your Liquid Products?

No leakages

Leakages cause waste to producers and ultimate loss. No business person would want to lose because if the consumers are aware that the products are leaking, they won’t buy them.

Additionally, leaking products are unhygienic because leakages attract ants, pests, and other insects to your products. Bags that are not leaking will not attract these rodents and insects. This is the reason why you should consider using liquid bags for your products.

Customization

Liquid bags have a large surface area that allows branding, design, graphics, and different colors. With these bags, you can have unique bags and distinctive products. You can design them as you wish.

Chilling Response

Liquid bags chills fast when put in refrigerators. In some cases, you want your drink or water to chill fast after buying them; liquid bags are for you because they facilitate chilling.

Reusability and Recyclability

Liquid bags can be reused for other purposes without posing any health issues, provided what is being put inside is compatible with the bag. Additionally, the bags can be reprocessed to produce other products.

Portable

The liquid spout bags are made with materials that make them flexible and squeezable. They are also produced in different sizes, making them user-friendly—people involved in sports activities like these bags because they are portable.

Smooth Filling and Dispensing

For liquid bags, you can evacuate up to 99 % of the content from the bags without stress. It’s frustrating as a consumer to see that you can’t reach the content in a bag.

The producers would not want a bag that takes time to fill because it will slow business activities.

Storage Maximization

A warehouse can be costly; that’s why you must be aware of where you will store your products after producing your products. If the products produced require more space, it means more cost, which adds up to the total cost of production.

This is not the case with Liquid bags; they occupy less space, allowing you to produce more bags without stopping the production process because there is no space.

The materials used in manufacturing liquid bags are lightweight, flexible, and squeezable. This ensures that there is full maximization of space and reduces the entire cost of production.

Resistant

The bags are resistant to external factors such as light, water, moisture, and dust. The liquid bags are made up of layers that resist these contaminants.

12. Do You Have Different Sizes For Liquid Bags?

There are various Sizes of liquid bags available in the market for you.

We can make liquid bags according to your requirements, such as size, material, thickness, and printing color.

13. Is There A Possibility Of Liquid Bags Leaking?

It’s one critical thing that all customers should consider and be taken care of. These bags are made with a thickness that is suitable for fluids.

Liquid bags are impervious to cut leaks and, most important it’s resistant to puncture. You are assured that there will be no wastage through leakages.

Again, your products will not attract rodents, ants, and insects. The material used to make liquid bags is strong to external pressure and contaminants.

Plastics Packing Company is an expert in manufacturing liquid bags with overlaid layer structures that make bags durable, strong, resistant to puncture, and free from wear and tear.

14. Which Is The Standard Thickness Of A Liquid Bag?

There are various thicknesses for liquid bags. However, as a company, we use a standard of 2.5 mils to 8mils (70 to 200 microns) for our bags because this is strong enough to resist pressure and accidents.

15. What Kinds Of Liquid Products Can Be Stored Into The Liquid Bags?

Liquid bags are one of the packaging methods present in the market today; companies that produce liquid or fluids are using these bags. Mainly, these bags are used in vegetable liquids, liquid chemicals, juices, beverages, liquid prescriptions, and syrups.

16. How Do You Test The Sealing Of The Liquid Bags?

It is crucial to ensure that liquid bags have been manufactured in the right way without skipping important stages. This step gives clients assurance that the bags can hold the products.

Seal testing is done by using a machine that checks whether there is a leakage on the seals of the liquid bags. You can also check whether or not the bag is leaking using water. After this step, the liquid bag is approved for the storage of various products.

Sea Faith Plastics Packing Company conducts seal testing for seals, mostly for bags meant to store fluids because you don’t want wastage, and we want customers to feel that we care about their business and consumers.

17. What Are The Drop Test For Liquid Bags?

A liquid bag is released from a certain height to test whether it will burst or not.

It is done because the bag can sometimes drop accidentally, and you want to know whether it can burst or tear easily. It’s vital because it talks about the material used in its durable or not.

18. What Is Weight Testing For Liquid Bags?

It is conducted to assess whether or not the bags can withstand the weight in them. You can use pressure to conduct this test. Liquid bags can be prone to tear; therefore, doing this test is vital.

19. Do Liquid Bags Preserve The Taste, Aroma, And Nutrients Of The Inside Products?

Liquid bags are odor-proof. They are made with material that doesn’t allow the smell to be perceived or detected. After sealing the bags, it doesn’t matter how strong the smell is; it can’t be perceived until the bag is unsealed.

Some products have a strong scent, but you are assured it won’t be the case with the liquid bag. More so, the material used to make the liquid bags resists any scent from outside to interfere with the content in the bags.

Additionally, the material doesn’t react with the substance in the bags, meaning that the content’s aroma, taste, and nutrients remain original uncontaminated.

20. Are Liquid Bags Eco-Friendly?

In recent years, companies have taken it seriously on matters that touch our environment. The nags that are manufactured are biodegradable, making them eco-friendly.

On top of that, it’s becoming an international concern, and now some guidelines and measures ensure that packaging materials are not a threat to our environment.

We also care about our environment; we’re manufacturing liquid bags and other products using biodegradable materials.

21. Can You Print Color On The Liquid Bags?

We want our customers to brand their products as they wish; therefore, we make bags with printable materials. Our bags, pouches, and packs can be printed.

As a company, we are employing current printing methods; this is incredible because we can create awareness about our products. More so, some products require information about their approval, and dates should be visible.

We give you remarkable craftsmanship and production for your products.

22. Can Ants, Rodents, And Pests Enter The Liquid Bags?

Liquid bags are resistant to ants and insects, and they can’t reach the content in the bags. However, this is not the case with rodents. It’s therefore, critical to keeping your products in a protected area out of rodents’ reach.

23. Are Liquid Bags Complied With FDA Requirements?

Approval by legal authority is critical, especially for edible items. You don’t want to put your health and that of your customers at risk.

FDA and ATSMA approve all our products, such as packs, bags, and pouches. It’s proof that the quality of our bags has met all the requirements. Be assured that our liquid bags will retain the freshness of your products.

24. Do Liquid Bags Pose Any Health Issues?

As we have stated, relevant legal authorities approve these products. Therefore, you can be assured that our products are standard.

Furthermore, the material used to make liquid bags don’t shed or react with the content, meaning that the content remains fresh.

25. Is There A Limitation About Liquid Bags The Highest Quantity I Can Order?

Sea Faith Plastics Packing Company has enough human capital to meet all demands. Therefore, there is no limitation to what you can order.

26. What Are The Temperature Requirements For Liquid Bags?

Liquid bags can be stored in different temperatures. However, our company gives specific instructions on the suitable temperature that fits each product; therefore, it’s important to follow them to enhance your product’s longevity.

27. Can Liquid Bags Be Reused?

All our packaging bags can be reused. The only challenge that you may experience is cleaning it. However, there is no problem with using the bag again, provided what you are carrying is compatible with the liquid bag.

28. What Are The Minimum Order Quantity Of The Liquid Bags?

We required customers to start at least 5,000 pcs for liquid bags without printing.

For printed liquid bags, we are required to start 30,000pcs, However, this doesn’t mean it’s a must; exemptions depend on our client’s agreement.

29. For How Long Can Content In A Liquid Bag Remain Fresh?

Our liquid bags are known for storing products for a long duration of up to ten years. What mostly determines longevity is the substance stored on the bag—some products last longer than others.

30. Which Are The Steps To Follow When Making An Order?

- Analyze Customers Requirements

- Evaluate Your Design Artwork ( Note : Printing Colour, Coverage)

- Offer Quotations and Send PI

- Printing Artwork or Samples Approval

- Arrange Production and Delivery

- After Sales Services and Repeat Order

31. Is It Possible To Have A Liquid Bag With A Spout?

Yes, this is possible with Sea Faith Plastics Packing Company; this is our specialty to ensure that all demands of our customers are met. You only have to tell us that you want liquid fit with spouts, and you will have them as you have requested.

The only challenge is ensuring the spout remains closed so that air does not enter the bag. Again, the spout must remain clean to avoid contamination.

32. Is There A Difference Between Liquid Bags And Liquid Pouches?

A liquid bag is a general name that refers to all bags and pouches. However, all pouches are not bags because there are other liquid bags like liquid Mylar and plastics.

33. Does Sea Faith Plastics Packing Company Give Samples To The Customers?

We give samples to our customers to test whether or not the liquid bags are suitable for their products. Unless the customers are making specific demands, the samples are free.

After using the content in liquid bags and you refill it does the bag offer protection to the refilled products?

Liquid bags retain their potential resistance against external barriers such as air, dust, and moisture. However, the closure will determine the freshness of the content.

34. What Are The Functions Of The Layers Of Liquid Bags?

In many cases, liquid bags are made up of inner, middle, and outer layers. The inner layer is responsible for retaining the freshness of the content by not shedding or reacting with the content. The middle layer creates the room for designing the bags as you desire.

The external layer protects the content from external contaminants such as ants, oxygen, water, and dust. Additionally, it offers protection for the graphics such as names, text, and images printed on the middle layer.

35. Do Liquid Bags Lead To Business Growth?

The liquid bags production process has created job opportunities for employees and investors. The living standards of these people are no longer the same. This area has become more lucrative because the demand for liquid bags is increasing day by day.

Furthermore, the businesses that were having problems in packaging their products now have a solution. They can use these bags to store their goods. And production is increasing to meet the high demand in the market. More investors are joining the business, and creativity and innovation are on rising as a result.

More so, customers are increasing because people can buy products stored in liquid because they are portable and flexible. People who are involved in sports activities or exercises can carry drinks using these liquid bags.

36. How Do Liquid Bags Compare With Other Packaging Methods?

Liquid bags and bottles are both used for packaging fluid or liquid products. Both offer resistance to the external factors and don’t contaminate the content in them. However, various reasons make liquid bags the better option.

Liquid bags are flexible.

Liquid bags are lightweight, portable, and squeezable. This is not the case with bottles; if you squeeze them, you can break or distort them completely because they are not meant to be squeezed.

For liquid Bags, you can squeeze them, and they will retain their shape and form. You can carry these bags when you are walking or jogging because they are lightweight.

Cost of Production

Liquid bags require less energy to produce compared to bottles. Therefore, the cost of production is less. In the end, the overall cost of liquid is less compared to that of bottles.

Easy Transportation

Liquid bags are transported easily than other packaging methods because they require fewer trucks to transport them. This is because they are lightweight and occupy less space. For the bottles, more trucks will be required because bottles require more space.

Lasting Artwork

The middle layer is printable, while the external protect the images, text, and other graphics from being erased. The material used to make liquid bags is the best for you because you can brand products as you wish. Bottles are not easy to design.

You realize that bottles have stickers because printing is not easy. This form of printing is not lasting because it can wash out, and the message fails to reach the intended clients. This makes liquid bags more attractive and user-friendly.

Warehouse Efficiency

Bottles occupy more space resulting in a few bottles being stored in a warehouse. The production may be stagnant because of a lack of enough space to store your products. However, with liquid

bags, production flows because bags require less space, meaning you will have maximum space utilization.

38. Which Information Is Required To Offer When Asking An Quotations?

The temperature of the products tells us whether the products are cold, hot, or warm. This will help us make bags that will fit you best.

State the product you need to store in the Liquid bags. We want to select the best material suitable for your product, and that’s why we need to know which product you are dealing with.

Let us know the target audience; this helps us design the liquid bags with features that are suitable to such an audience. For instance, liquid bags meant to carry children’s products will need to have more attractive images.

Display method; let us know whether you want your liquid bags to appear vertical or horizontal.

Define your inner spout diameter size.

Give us detailed information on liquid bags size, thickness, material, printing color, liquid products types and we will update quotations to you soon.

39. Which Benefits Do You Receive When You Buy Liquid Bags From Sea Faith Plastics Packing Company?

Standard Liquid Bags

When you make orders, you will have quality liquid bags. The company chooses material to make bags based on the content that you will store in it. We are experts in this area, and we have been in operation for many years.

Steady Supply

You don’t want to stop in the middle of the production process because you don’t have enough liquid bags to store your products in.

Sea Faith Plastics Packing Company ensures that you meet your customers have enough of your products. That is why when your orders are approved, we produce your liquid bags within a period of 24 hours.

If you are looking for a reliable supplier or are currently having a problem with your supplier, we are here for you to make your orders, and you will have bags and demands that you made.

Legal Compliance

Our products, pouches, bags, or any other type of packs, are approved by the FDA. You want to have less stress when conducting business. You don’t want to have the hustle of using liquid bags that are not approved.

Reach us today for products that have met all legal requirements.

Customization

Our liquid bags are customizable, meaning you can design them in the shape, color, and graphics you desire. The company ensures that you produce products with enough surface area to print logos, text, and images.

Fair Price

Our products are affordable; we have modern production methods that we employ, which reduces the overall cost of production, meaning that our customers get our products at a lower cost.

Durable Liquid Bags

Plastics Packing Company uses strong materials that produce durable bags. Our bags can resist punctures and external factors such as UV light, moisture, and dust.

Compatibility

Plastics Packing Company gathers relevant information about the type and content you want. Therefore, when making liquid bags, we produce bags that are compatible with your product. Your customers can enjoy your products without fear that your products may be contaminated.

Samples for Testing

We give samples to our customers for free. They can test the liquid bags whether or not they are fit for their products unless the customers make other demands on the type of liquid bags they want.

Eco-friendly Liquid Bags

We produce biodegradable bags. Our bags are not a threat to the environment. Our customers are loyal to us because they are sure that we care about their well-being and our environment.

40. What Are The Additionally Features Fit On A Liquid Bag?

Spout

We can add a spout to a liquid bag when the customer makes such requests. The feature helps the smooth filling and dispensing of the content in the liquid bag.

It’s an advantage to both the consumer and the producer because the producer will fill the bag fast while the consumer will not have wastage because they can evacuate up to 99% of the content.

Valve

Valve is added to a liquid bag to make the bag more effective and consumer-friendly. By adding the valve, the content freshness and taste are guaranteed because gases that make content stale are released.

Additionally, the valve doesn’t allow air from outside to enter into the bag, increasing the product’s longevity.

41. Which Are The Precautions When Using Content Stored In The Liquid Bags?

Liquid bags made with non-biodegradable materials can be a threat to the environment. When they are carried into water bodies, they can threaten the aquatic life in these water bodies.

On top of that, when they are burnt, they increase the level of carbon dioxide in the air. However, for our liquid bags or any other non-biodegradable packs, we give specific instructions on how to dispose of them.

Please follow these instructions so that you can help us take care of our environment.

Furthermore, when you buy consumable products and realize that they have an unusual odor, feel, or color, don’t consume such products. The product may be contaminated, and we want you to be safe.

If you have any inquiries about liquid bags, please contact us. Thank You!