- sales@plastics-packing.com

- + 86 138 2350 2792

In order to avoid disappointing the customer with the bag that he expects, we usually ask you to prepare the printing artwork and design outline and send it to us first. If it is necessary, we will make some corrections and suggestions based on your printing artwork, and then send it to you again for review and confirmation. If you are satisfied, we will start to arrange to do printing copperplate and production procedures etc.

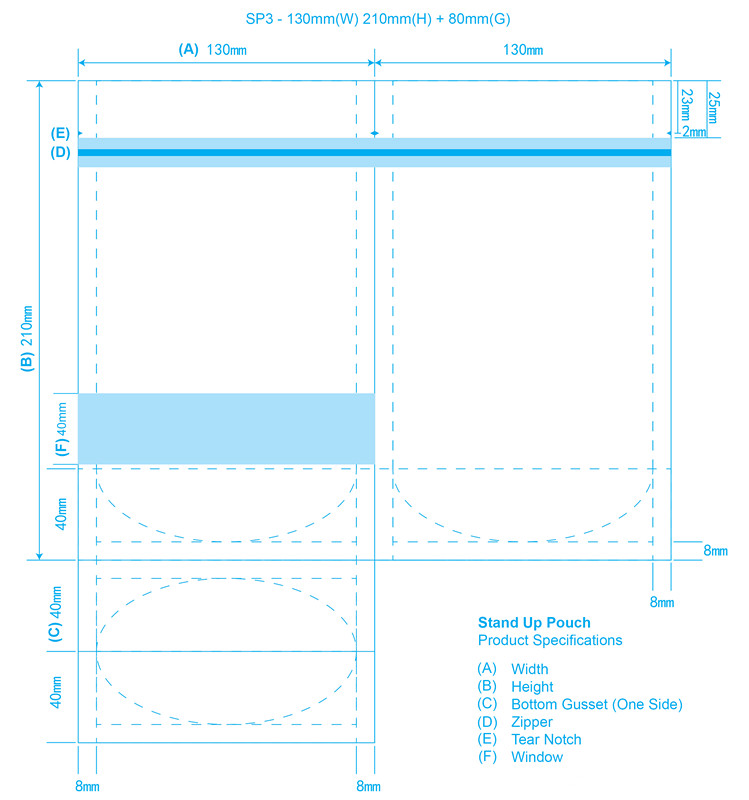

After communicating and explaining to us, tell us what type of packaging do you need. our in-house graphics department that will send you a blank template according to your pouches shape you need

Every detail about the dimensions, opening directions, filling, tear notch, zipper, the valve of the expected bags will be taken care of illustrated well on the outline.

After finishing template preparations, we will send you an email. that is what your artwork designing department will use to put well -outlined artwork into our blank template.

As Below is an example of a stand-up pouch blank template we send to our customers.

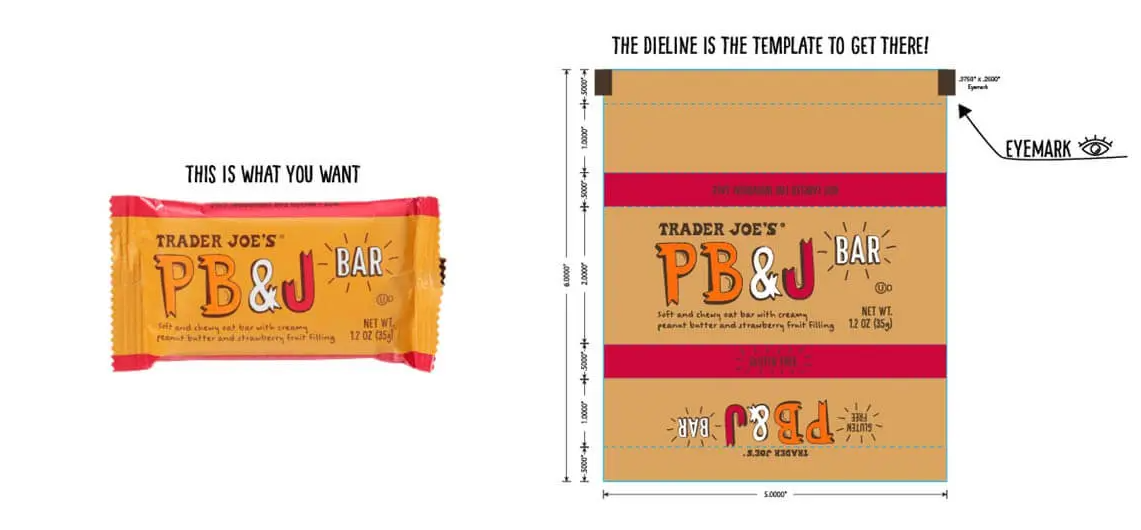

When done with the artwork, you will send it to us again. We will double-check it in details, make any changes where needed, correct the distortions and send you the final high- quality printing artwork for confirmations

when we received your artwork approval proof, it’s time for you to decide whether we can start to print or not. If you need anything changes again, and your artwork needs to return to our designing department.

After you confirmed the artwork, if you have samples bags in your hand, you can send to us your sample bags or you agreed to make bags as you confirmed the printing artwork to make plus purchase order.

If you offer jpg versions, please make sure to the resolution of your image format.it has to be Excellent quality and high clarity pics .

But It’s better to offer printing artwork files in PDF, AI, CDR, PSD version.

Eye marks are thin and rectangles mostly found on the pouch corners. They are used by printing machines eye sensor to “sync” the pouch endpoint for perfect image printing.

These eye marks should and are made of the darkest colour that is 100% tint. A 100% black colour and a white underneath trapping of 0.5 mm are the best.

It means that if the background is to be black, the eye marks are supposed to be white in colour

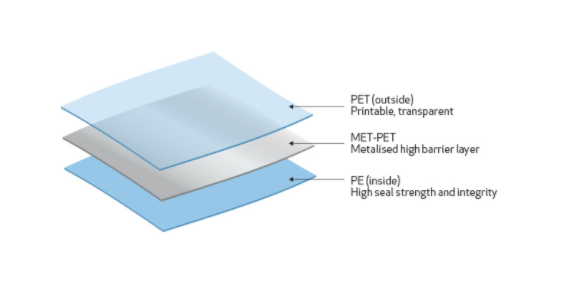

If you confirmed the packaging solution, so the next step is to choose a suitable material structure and thickness according to your inside packed products and inside products weight. Each material has a certain physical, chemical and functional property which makes it suitable for different types of packing uses.

Most packaging is made up of multi-layer material. Each layer has a unique purpose. The composition of materials used is primarily made up of an outside layer, which is a transparent barrier that is printable for you to brand with your marketing, a middle layer that provides high oxygen barrier protection so the integrity of your goods is maintained and an inner layer.

We have devoted 30+years to developing world-leading innovative and sustainable packaging manufacturers, so we can serve our customers the best packages solutions.

If you have any flexible packaging bags and OPP block bottom bags requirements, please free to email us.and we will give you a reply within 24 working hours.